Enhancing Product Aesthetic Appeals: The Function of In-Mold Decorations in Production

Wiki Article

Mastering In-Mold Decorations: Approaches, Patterns, and Ideal Practices for Optimum Results

In the world of manufacturing, the art of in-mold decorations stands as a crucial element of product style and manufacturing. As industries consistently look for ingenious ways to improve visual appeal and functionality, understanding the intricacies of in-mold decors has actually arised as an essential ability. From selecting the appropriate materials to integrating sophisticated layout fads, the trip towards attaining optimal results in this domain is multifaceted. By delving into the approaches, fads, and ideal practices that underpin effective in-mold decoration processes, companies can unlock a realm of opportunities that not only raise the aesthetic allure of their products but likewise streamline production efficiency and boost customer interaction.Product Selection

Product choice is a critical aspect of understanding in-mold decors, as it straight impacts the top quality and resilience of the final item. When selecting materials for in-mold decorations, it is important to think about variables such as compatibility with the molding procedure, the desired visual end result, and the environmental conditions the product will certainly deal with. Thermoplastic products like polycarbonate, ABDOMINAL MUSCLE, and polypropylene are commonly made use of for in-mold decorations as a result of their convenience and capability to accomplish detailed layouts. These products use outstanding moldability, enabling producers to produce complex shapes and patterns with precision.Furthermore, the picked product must have excellent adhesion homes to ensure that the design adheres strongly to the substratum throughout the molding process. Attachment in between the material and the decor is crucial for protecting against delamination and ensuring long-lasting visual charm. In addition, products with high warmth resistance are liked for in-mold decorations, specifically for items that will certainly be subjected to elevated temperatures throughout their lifecycle. By meticulously selecting the proper product for in-mold designs, manufacturers can boost the general quality and sturdiness of their products, fulfilling the assumptions of both clients and end-users.

Design Innovation

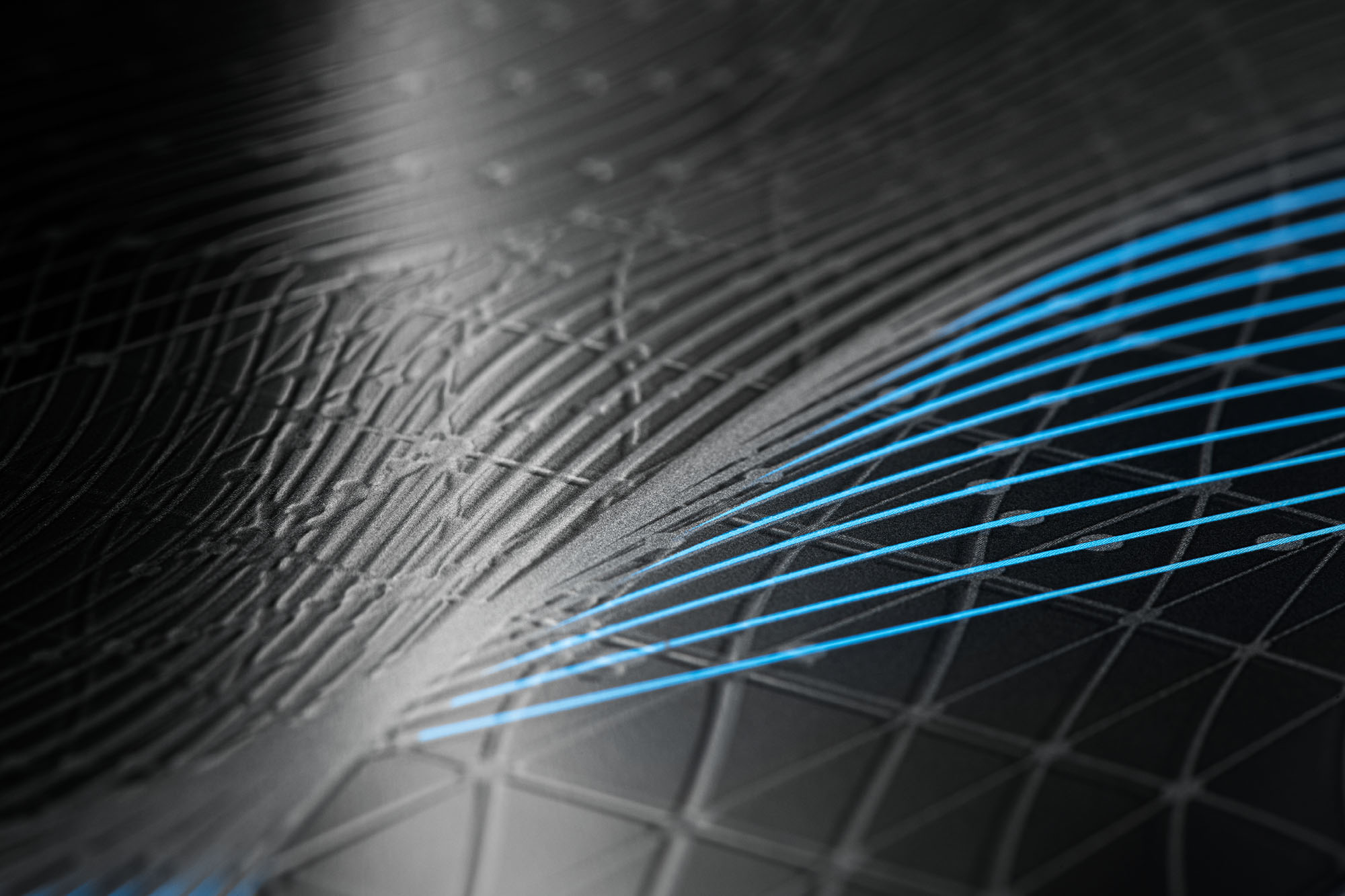

A vital variable in progressing the area of in-mold designs is the constant expedition and application of design innovation techniques. Style technology plays an essential function in improving the aesthetic allure, capability, and overall quality of items produced utilizing in-mold decoration procedures. By integrating cutting-edge layout elements, suppliers can separate their items in the market, draw in consumers, and remain in advance of competitors.Among the essential elements of style advancement in in-mold designs is the integration of detailed patterns, textures, and graphics that were previously challenging to accomplish with typical design techniques. Advanced innovations such as 3D printing and digital layout devices allow designers to create facility and comprehensive designs that can be flawlessly moved onto shaped components. Additionally, making use of vibrant colors, metallic finishes, and special effects like gloss or matte appearances can additionally elevate the visual appeal of in-mold decorated items.

In addition, style development extends beyond appearances to encompass useful enhancements such as ergonomic shapes, integrated features, and adjustable aspects that accommodate specific user demands. By embracing design innovation, suppliers can open brand-new possibilities for creative thinking, product, and personalization distinction in the affordable landscape of in-mold designs.

Manufacturing Effectiveness

Effective manufacturing procedures are necessary for translating the cutting-edge designs established in the field of in-mold click over here now designs right into high-quality ended up items that meet market demands and customer assumptions. In the realm of in-mold decors, production efficiency includes numerous essential facets that add to the general success of the production process.Automation not just speeds up the manufacturing procedure but additionally improves accuracy and repeatability, leading to an extra premium and uniform end product. In general, a holistic strategy to production effectiveness is paramount in taking full advantage of the potential of in-mold decoration methods and accomplishing optimum outcomes in the affordable market landscape.

Quality Assurance Procedures

What are the essential techniques for ensuring stringent top quality control measures in the realm of in-mold decors? Quality control procedures are critical in in-mold design procedures to guarantee the manufacturing of flawless and top quality finished products. One critical approach is the application of strenuous examination procedures at every phase of the manufacturing procedure. This involves carrying out comprehensive aesthetic assessments, dimensional checks, and shade uniformity assessments to recognize any problems or variances early.Utilizing sophisticated modern technologies such as automatic assessment systems can likewise boost the quality assurance process by supplying exact and dependable data for analysis. These systems can discover flaws that may be missed by manual inspections, thereby enhancing overall item quality and consistency.

Routine training and advancement programs for workers associated with the in-mold decor procedure can also contribute to preserving top quality requirements. By enlightening staff on finest methods, high quality expectations, and the importance of focus to detail, business can cultivate a society of quality consciousness throughout the company.

Consumer Appeal

To boost the bankability additional reading of in-mold decor items, catering and recognizing to customer choices play an essential duty in identifying their allure and success. Supplying modification alternatives such as personalized designs, shade variations, and textural components can dramatically boost the appeal of in-mold decor items.

Verdict

In-mold decors provide a functional and effective method to boost item appearances. By carefully choosing materials, welcoming ingenious layouts, maximizing manufacturing processes, implementing top quality control procedures, and prioritizing customer appeal, producers can accomplish ideal outcomes. It is important for firms to consistently adapt and boost their techniques to stay competitive in the market. In-Mold Decorations. Understanding in-mold designs calls for an all natural technique that considers all facets of the production process to ensure success.In the realm of manufacturing, the art of in-mold designs stands as a pivotal facet of item layout and production. Design technology plays a vital duty in boosting the aesthetic allure, functionality, and overall high quality of items made making use of in-mold decoration processes.One of the vital elements of design development in in-mold decors is the assimilation of complex patterns, structures, and graphics that were formerly challenging to he said accomplish with typical decor methods.Effective production processes are necessary for equating the innovative layouts developed in the area of in-mold decors right into premium ended up products that satisfy market demands and consumer expectations. Providing personalization choices such as personalized styles, color variations, and textural elements can dramatically enhance the allure of in-mold decor items.

Report this wiki page